Pipe stress analysis

Comprehensive pipe stress analysis services ensure structural integrity and compliance under all operating conditions. From static and dynamic evaluations to thermal flexibility checks, vibration control, and surge analysis, we deliver optimized support design and detailed reporting to safeguard equipment, prevent failures, and meet industry standards.

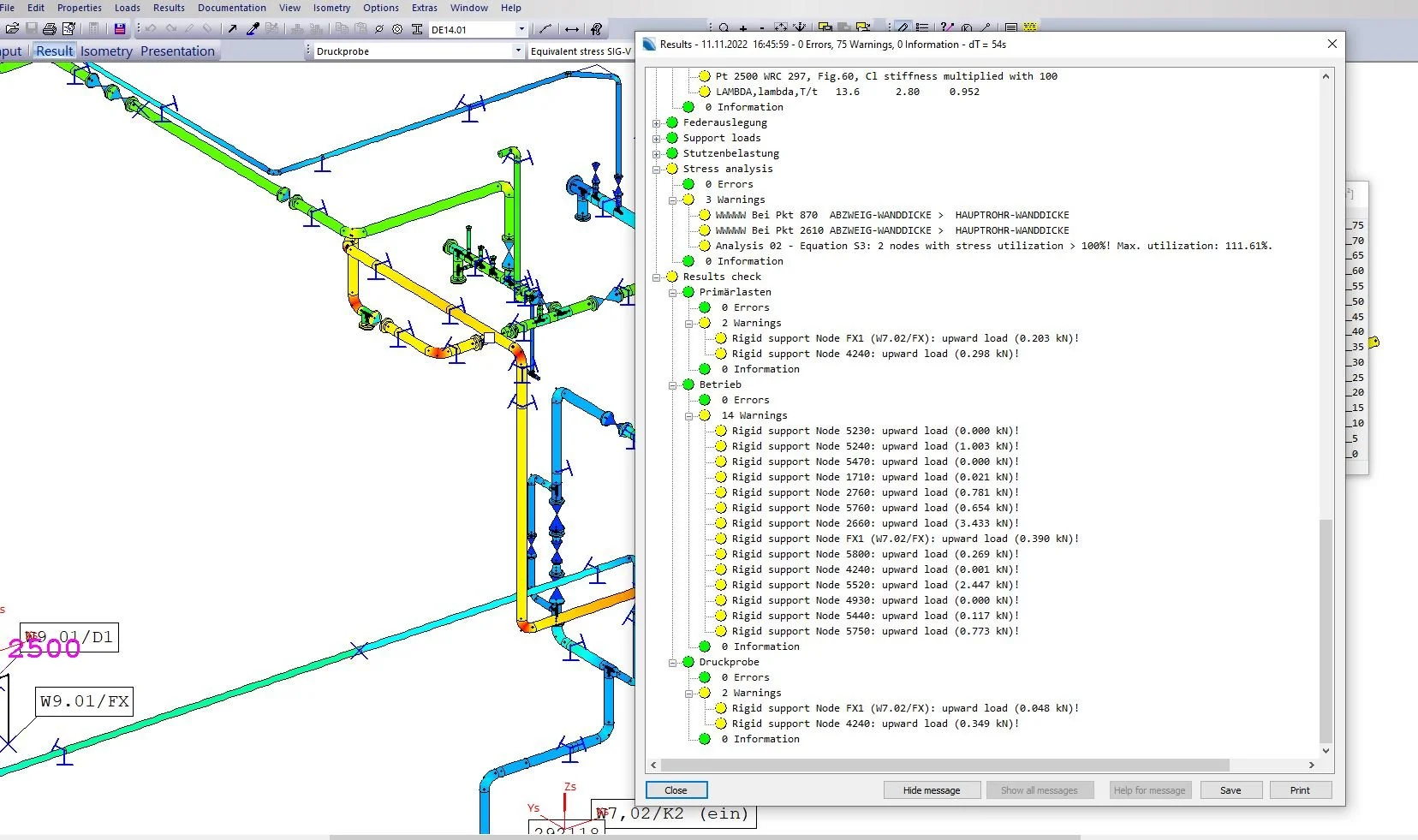

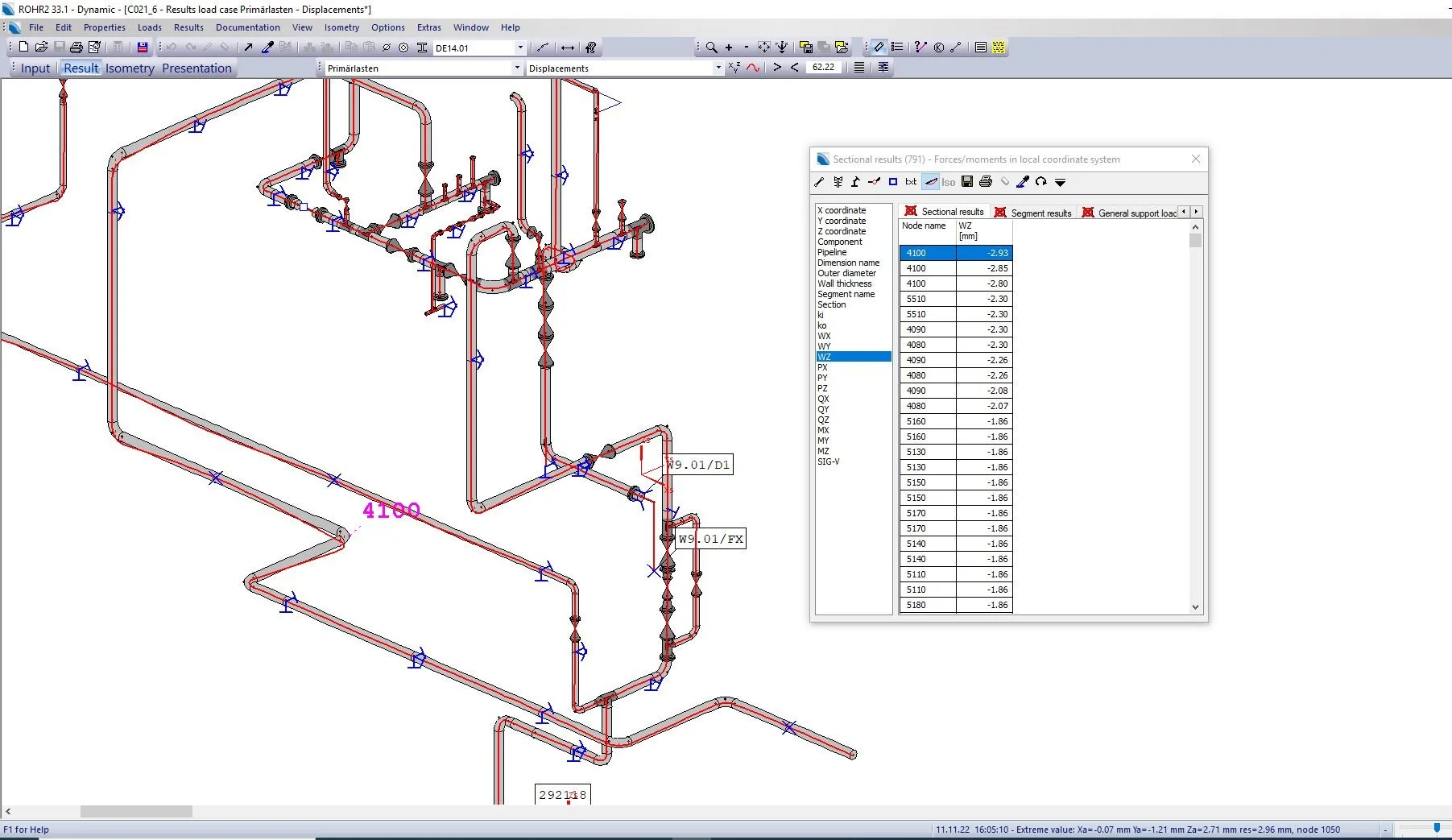

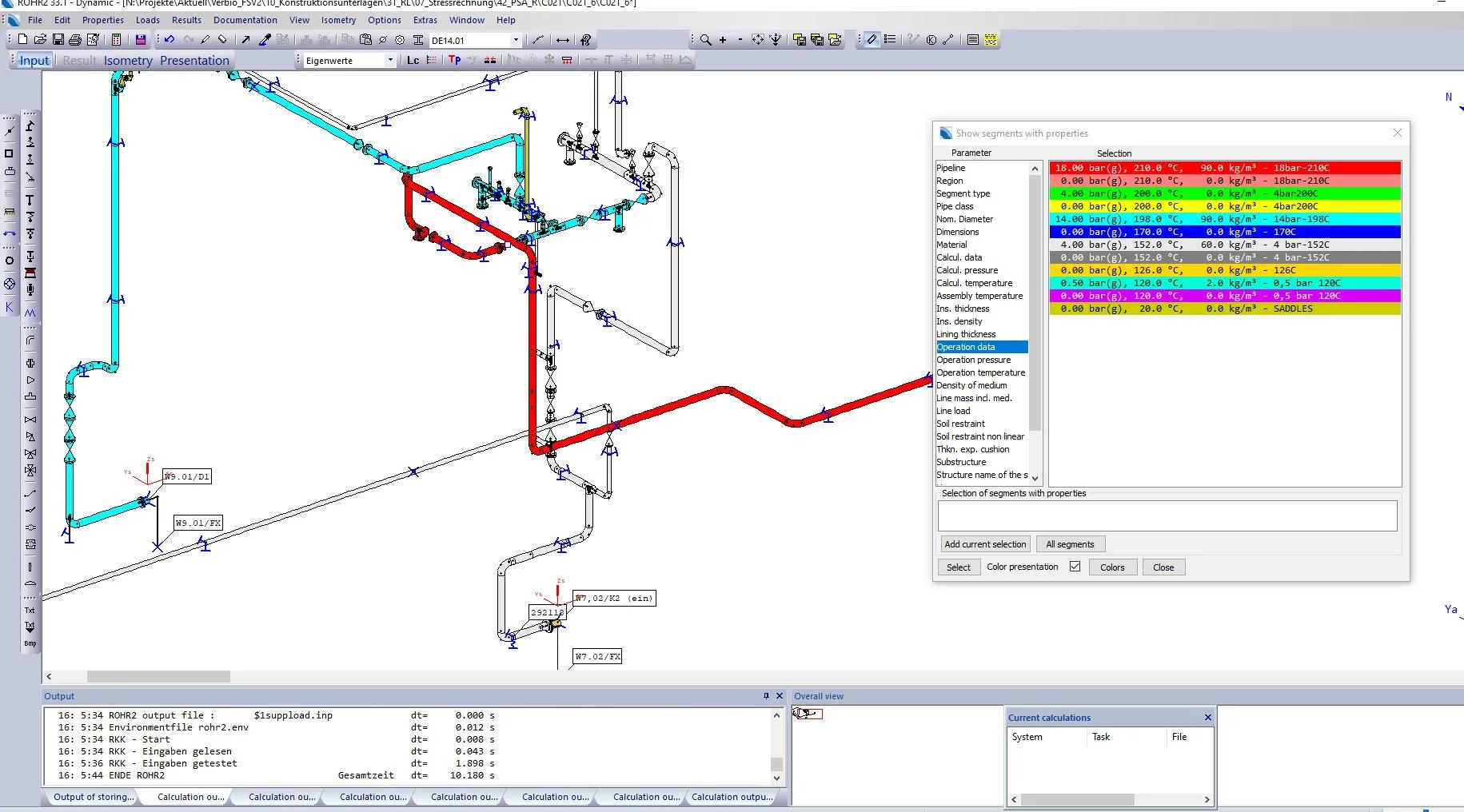

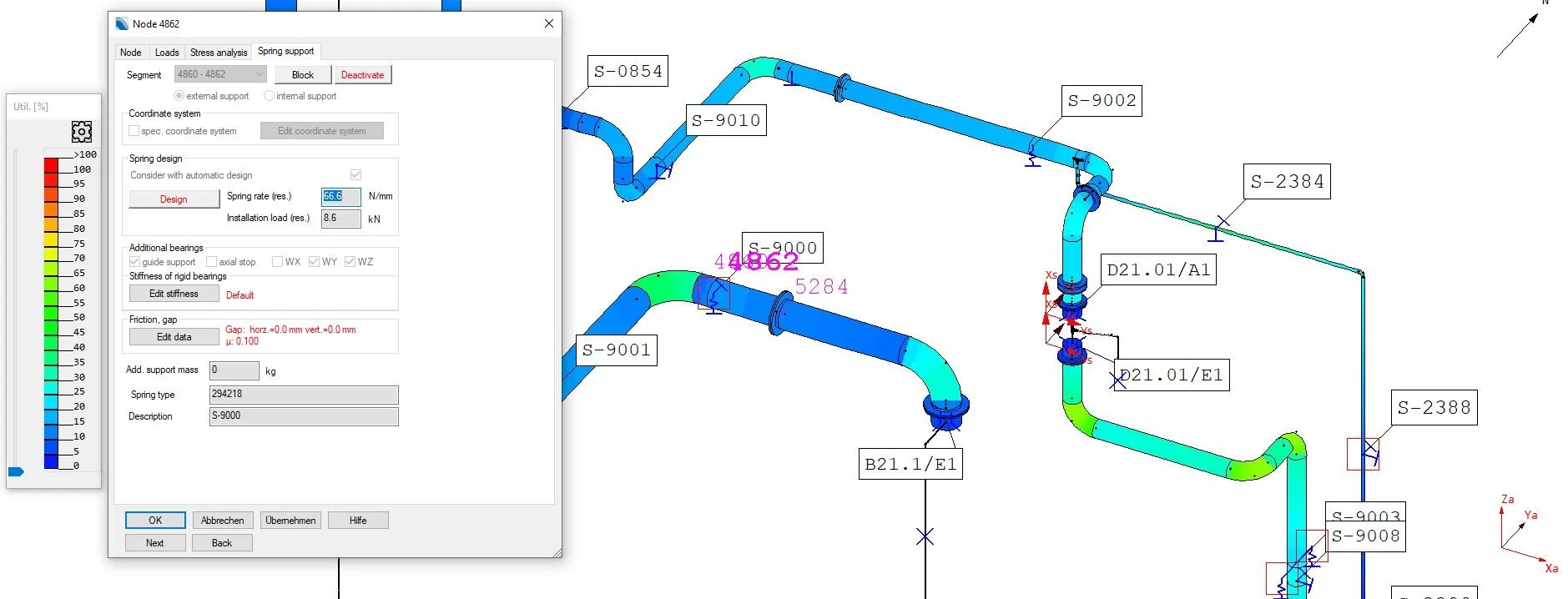

System Modeling And Load Cases

Comprehensive piping models for static and dynamic load case evaluation.

Stress Distribution ANd Compliance

Stress distribution analysis to ensure compliance with ASME, EN, and international codes.

Equipment And Nozzle Load Verification

Protecting critical equipment through accurate load verification.

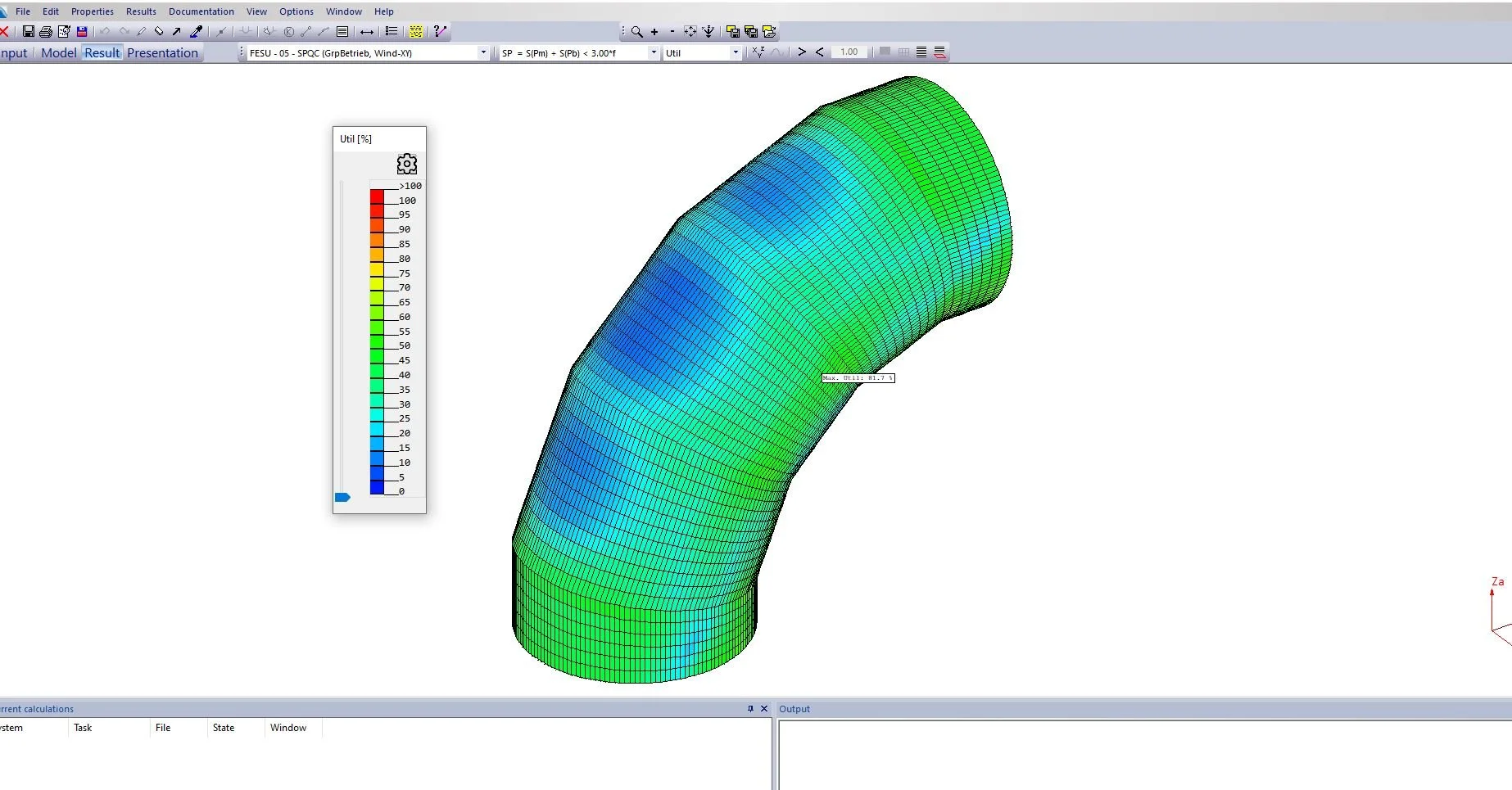

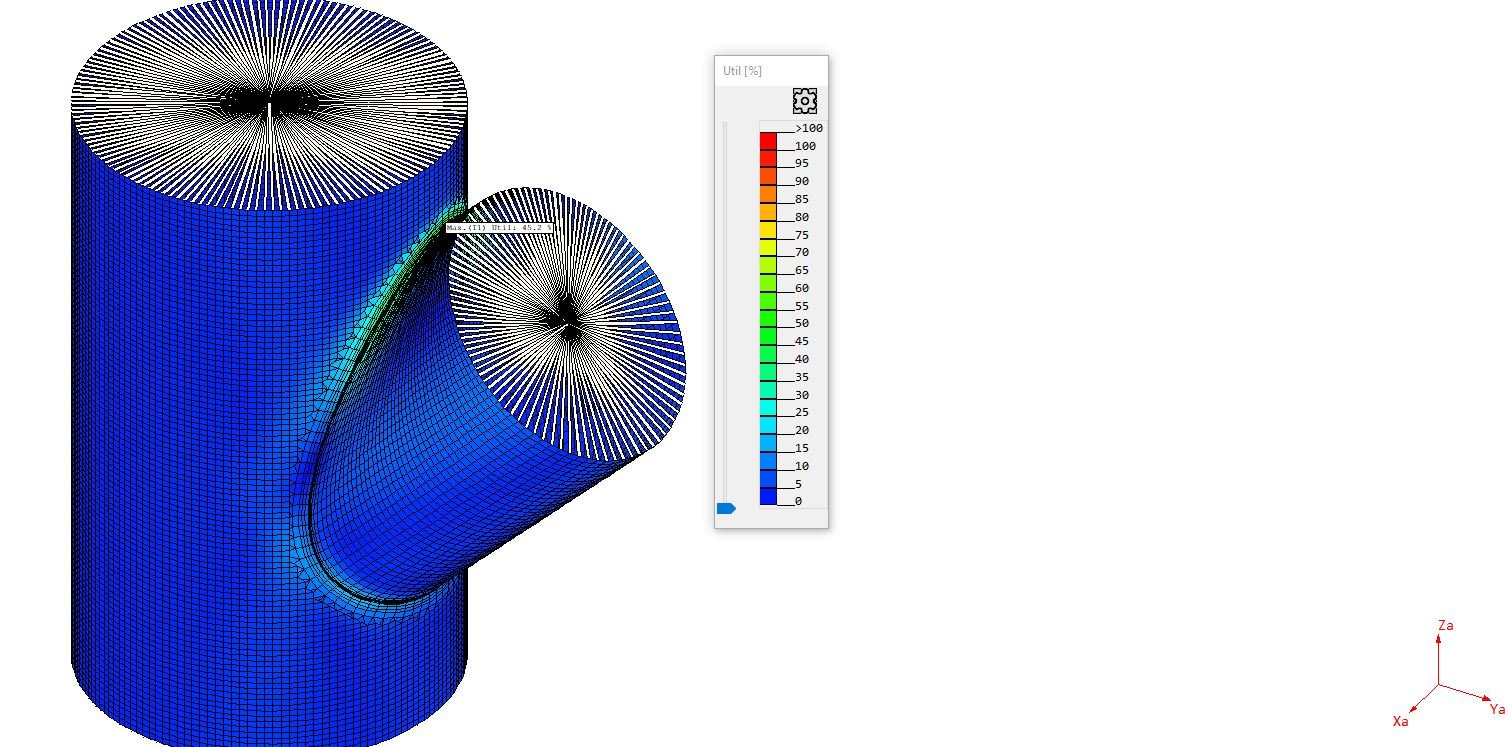

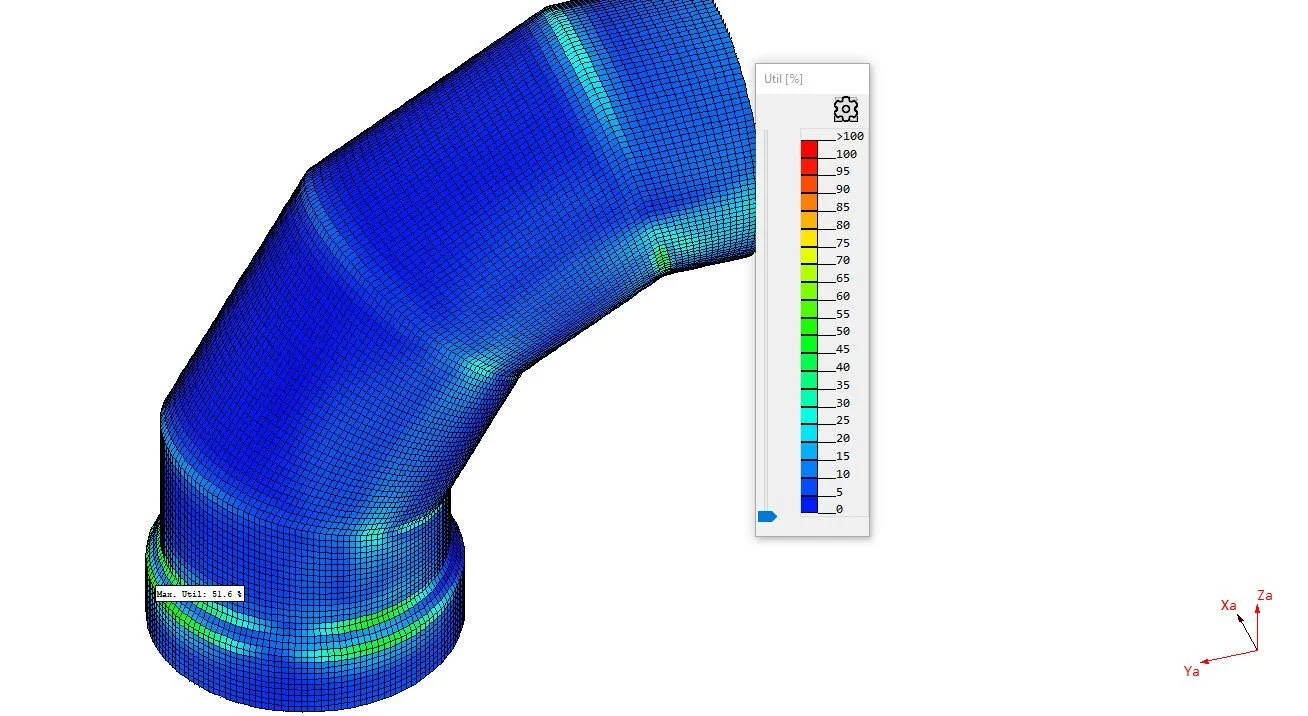

Advanced Finite element Analysis

Finite Element Analysis for local stress concentrations and non-standard components

Our pipe stress analysis Capabilities

-

Full load-case evaluation (pressure, temperature, weight, occasional loads) – including non-linear effects and time-history analysis.

-

Simulation of all operating cycles to guarantee stress levels stay within code limits and prevent fatigue or over-straining of nozzles and supports.

-

Detailed engineering of spring hangers, constant hangers, snubbers, rigid struts and sliding supports using with exact load tables and positioning drawings.

-

Leak-before-break proof including bolt pre-load, gasket compression and tightening torque tables.

-

Protection of pumps, vessels, heat exchangers and compressors including nozzle load reports.

-

Earthquake, wind/snow/ice and relief-valve reaction forces – fully integrated into the piping model.

-

Acoustic-induced (AIV), flow-induced (FIV) and mechanical vibration analysis.

-

Transient simulation of pump trips, valve closures and slug flow – time-history forces transferred directly into stress model.

-

Soil-pipe interaction, settlement and thermal expansion.

-

Stress and flexibility analysis of FRP/GRP, PE and PVC systems.

-

Local stress concentrations on trunnions, saddles, lifting lugs, vessel clips and non-standard components.

-

Full verification of pipe racks, platforms and support frames.

-

Colour-coded stress isometrics and prioritised critical-line lists for inspection planning.

-

Root-cause analysis and remaining-life assessment.

-

ROHR2 (incl. ROHR2iso & Stoss)

SINETZ

PROBAD

Caesar II

AutoPIPE

ANSYS

Ready to ensure your piping system is safe and compliant?

Pipe stress analysis is critical for preventing failures, ensuring code compliance, and protecting equipment under all operating conditions. Our advanced analysis services cover static and dynamic loads, thermal expansion, and vibration risks—helping you achieve reliability and safety across complex piping networks.

Prevent costly failures and extend system life

Ensure compliance with ASME, EN, and international codes

Optimize support design and reduce operational risks